What is an S-curve?

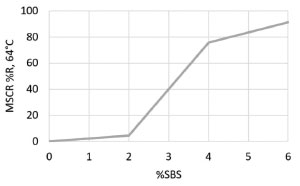

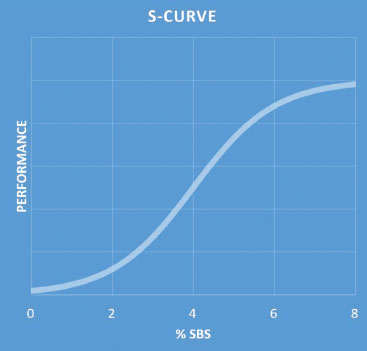

SBS polymers are most effective as asphalt binder modifiers when they form

a continuous polymer-rich network. When this happens, asphalt binder –

originally a visco-plastic liquid – becomes a visco-elastic solid. The transition is

accompanied by an order of magnitude improvement in asphalt binder toughness

and durability performance. However, the performance improvement does not

follow linearly with an increase in SBS loading. Rather, it follows an “S-curve.”

Literature

Why Asphalt Binder Modification

Follows S-curve

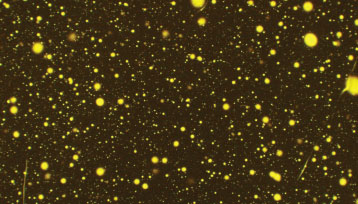

At low dosage levels (0- ~2-3 wt%), SBS typically forms a discontinuous

polymer-rich phase in asphalt binder. This means that while the asphalt binder’s

performance properties improve, the progress is rather small. The majority of

asphalt binder still lacks SBS presence. This performance region is represented

by the curve’s initial flat

part in Figure 1.

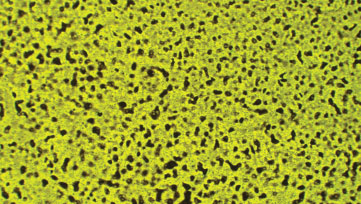

Figure 2: UV micrograph example of a discontinuous polymer-rich

phase in asphalt binder.

Figure 2: UV micrograph example of a discontinuous polymer-rich

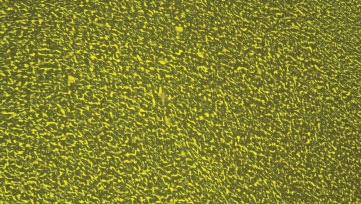

phase in asphalt binder.When SBS dosage increases past ~2-3 wt%, the polymer starts to form a semi-continuous polymer-rich phase in the asphalt binder. At this point, the asphalt binder’s performance properties improve at a much higher rate. The previously-separated polymer-rich regions start to come in contact with each other. This performance region is represented by the curve’s steep part in Figure 1.

Once the SBS dosage reaches 6-8 wt%, the polymer forms a continuous polymer-rich phase, transforming the visco-plastic liquid asphalt binder into a visco-elastic solid. At this stage, the asphalt binder’s performance properties are reaching maxima as the polymer network becomes fully interconnected. This performance region is represented by the curve’s top flat part in Figure 1. Kraton’s Highly Modified Asphalt (HiMA) technology is an excellent example of a paving application relying on the continuous polymer-rich network effect, combined with special low-viscosity SBS grade.

Remarks

For maximum performance and reliability per SBS dosage, it is always recommended to target the S-curve’s top part (continuous polymer rich phase). In this part, the polymer modified asphalt (PMA) properties are very stable and the performance/cost ratio of the formulation is maximized. On the other hand, when the formulation falls onto the steep part of the curve, small changes in SBS/binder ratio or material consistency can seriously shift the performance parameters, leading to the properties’ instability.

The S-curve’s shape depends on many factors including:

- Asphalt Binder Chemistry

- Formulation Conditions

- SBS Polymer

- Crosslinking

- Properties Being Evaluated

where the material is stretched beyond its linear viscoelastic range. This includes

- Softening Point

- Multiple-Stress Creep-Recovery (MSCR) % Recovery

- Force Ductility

- Elastic Recovery Tests

Figure 3: UV micrograph example of a semi-continuous polymer-rich

phase in asphalt binder.

Figure 3: UV micrograph example of a semi-continuous polymer-rich

phase in asphalt binder. Figure 4: UV micrograph example of a continuous polymer-rich

phase in asphalt binder.

Figure 4: UV micrograph example of a continuous polymer-rich

phase in asphalt binder.Conclusion

Continuous polymer-rich network in asphalt binder results in numerous performance

benefits, such as:

- Softening Point

- Multiple-Stress Creep-Recovery (MSCR) % Recovery

- Force Ductility

- Elastic Recovery Tests

Using high loading levels of SBS may not always be feasible due to incompatible asphalt binder or high formulation viscosity. Fortunately, Kraton offers many specialized low-viscosity SBS grades with enhanced asphalt binder compatibility. Our global technical service and research team is available to provide formulation assistance.

Below are sample S-curves in conventional, compatible paving asphalt binder grades modified with triblock SBS.