新闻报道

Celebrating Five Years of CirKular+™: Enabling Plastics Upcycling & Circular Economy

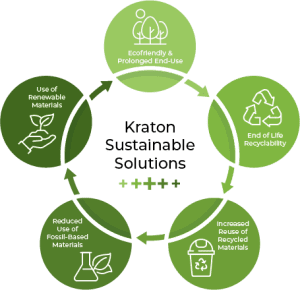

In 2020, Kraton launched its CirKular+™ product line to support efforts to increase the use of mechanically recycled plastics, reduce plastic waste, and enhance recyclable design through the plastics industry. Today, we celebrate five years of CirKular+ technology, which enables increased use of recycled plastics, performance enhancements, and circularity with a measurable impact.

In 2020, Kraton launched its CirKular+™ product line to support efforts to increase the use of mechanically recycled plastics, reduce plastic waste, and enhance recyclable design through the plastics industry. Today, we celebrate five years of CirKular+ technology, which enables increased use of recycled plastics, performance enhancements, and circularity with a measurable impact.

Why CirKular+™?

Industry pressure to decarbonize has further emphasized the importance of sustainability and the need for a circular economy. A focus on circular design has become a critical part of corporate sustainability and innovation strategies, aiming to increase end-of-life recyclability and reduce the use of fossil-based alternatives. We see tightening regulatory pressure around recycled content and emissions disclosures, with an increasing emphasis on producer responsibility to invest in reuse, reduction, and recycling efforts.

At Kraton, we believe that innovation plays a critical role in supporting the industry journey toward a circular economy. CirKular+ innovative solutions were specifically designed to address three key industry challenges:

At Kraton, we believe that innovation plays a critical role in supporting the industry journey toward a circular economy. CirKular+ innovative solutions were specifically designed to address three key industry challenges:

- Enable end-of-life product recyclability: Supporting a mono-material polyolefin-based approach

- Improve inferior PCR quality: Post-consumer recycled (PCR) plastics typically have poorer mechanical properties compared to virgin plastics

- Increase reusability of mixed plastic waste: Difficult-to-recycle streams are frequently sent to landfills or incineration

CirKular+ enables a holistic approach to plastic product life cycles, including considerations for recyclable design, reducing fossil-based plastic usage, and expanding the use of recycled plastics even in high-performance applications. All of these benefits can be achieved with lower carbon emissions throughout the product’s life cycle.

What is CirKular+™?

Today, CirKular+™ offers a wide range of performance enhancement solutions to enable a circular economy. The CirKular+ portfolio includes four specialized series:

- Performance Enhancement Series: Designed to boost the mechanical properties of polyolefin-based PCR (Post-Consumer Recycled) and PIR (Post-Industrial Recycled) materials—enabling more demanding applications and supporting recyclable design. Recognized by RecyClass and APR for use in HDPE and PP containers, as well as PE films by APR, this series delivers a virgin-like performance even at high PCR content levels. It enables recyclates to retain mechanical strength across multiple reprocessing cycles with minimal stiffness loss, demonstrating up to a 500% improvement in performance with just 3–5% additive usage level.

- Compatibilization Series: Facilitates the mechanical recycling of mixed and contaminated plastic waste by increasing processability and improving formulation stability for a broad spectrum of resins with different polarities, such as polyolefins, PET, and polyamides. Our customers typically add them at a 1 to 5% loading level.

- ReNew Series (launched in 2022): Incorporates up to 100% ISCC PLUS certified renewable content, delivering on average an 85% reduction in GWP (Global Warming Potential) vs. fossil-based Styrenic Block Copolymers as a drop-in alternative. Three of Kraton’s styrenic block copolymer manufacturing sites have received ISCC PLUS certification.

- Paving Circularity Series (launched in 2025): Engineered to meet evolving paving industry needs to increase the usage of reclaimed asphalt and reduce greenhouse gas (GHG) emissions, the CirKular+ Paving Circularity Series enables incorporation of up to 50% or more reclaimed asphalt content in the asphalt mix in surface layers, while improving processability and performance.

How is CirKular+ Creating Value?

The journey to a circular plastics economy requires collaboration across the value chain. Since 2020, Kraton has been working closely with recyclers, converters, and brand owners to develop scalable circular solutions. We are proud members of both APR (North America) and RecyClass (Europe), aligning with global best practices and recycling standards. Since the launch of CirKular+, we have supported our customers across a wide range of applications, from Packaging to Automotive and Consumer products, to increase durability, maximize the use of PCR, and achieve recyclable designs. CirKular+ additives are successfully used in various processes, including injection and blow molding, extrusion, thermoforming, and cast and blown film lines. Beyond performance, CirKular+ supports ease of adoption: its solutions work within existing equipment and require no capital investment.

- Consumer Products – enabling recyclable design and maximizing PCR content

- Industrial pallets, totes and bins, and PET strapping made with 100% PCR content and virgin-like durability

- Food & beverage rigid packaging with up to 95% PCR content, with no trade-offs in aesthetics and functionality

- Multi-layer film packaging manufacturers are reducing production waste and enabling circular reuse in rigid applications

- Sustainable fashion through recycling of plastic cups & ocean plastics & textile recycling into beautiful new apparel designs

- Automotive applications by enhancing recyclable design for interior rigid and flexible parts based on TPE-S approaches, while incorporating recycled PP and nylon into exterior, interior, and under-the-hood parts

Since 2020, based on our internal estimates, CirKular+ has enabled the reuse of up to 250k tons of PCR globally, enabling a reduction of up to 500k tons of CO2 emissions, equal to preserving over 900k barrels of oil worldwide. Kraton’s CirKular+ technology represents a significant leap forward in advancing circularity within the plastics industry, demonstrating our commitment to sustainability and environmental stewardship.

相关产品和信息

延伸阅读

探索更多见解、新闻和成功案例。